Instrument Repair & Reconditioning Services By Brand

Our Class A ProcessMeets ANSI, ISA, ASME Standards

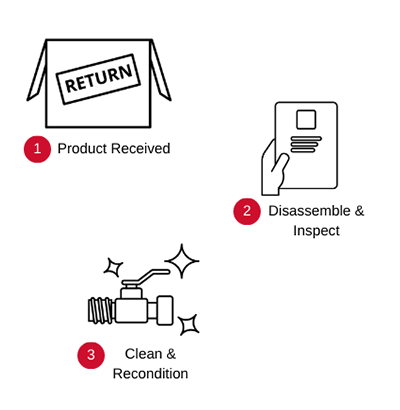

After receiving a customer’s instrument, we disassemble the instrument and inspect it to determine the “as found” state.

Wethen follow up with a full cleaning and reconditioning of the instrument.

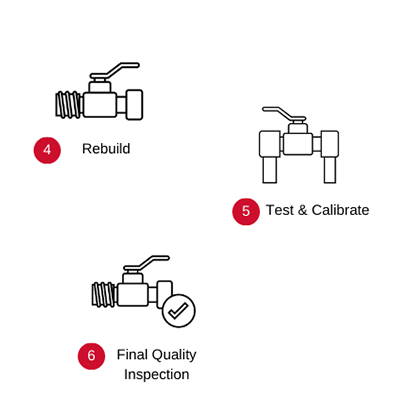

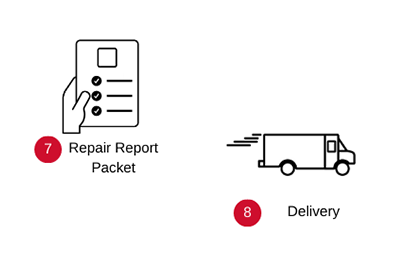

Following the reconditioning process, we rebuild the instrument – then test and calibrate to ensure it is functioning reliably.

We then ensure that the instruments go through a final quality inspection and finalize our process with an “As Left” document, which is sent with the instrument back to the customer.

Our Class A ProcessMeets ANSI, ISA, ASME Standards

After receiving a customer’s instrument, we disassemble the instrument and inspect it to determine the “as found” state.

Wethen follow up with a full cleaning and reconditioning of the instrument.

Wethen follow up with a full cleaning and reconditioning of the instrument.

Following the reconditioning process, we rebuild the instrument – then test and calibrate to ensure it is functioning reliably.

We then ensure that the instruments go through a final quality inspection and finalize our process with an “As Left” document, which is sent with the instrument back to the customer.

Why Choose Us?

Committed to quality

One-year warranty on parts and labor

Guaranteed 24/7 response time

Committed to quality

One-year warranty on parts and labor

Guaranteed 24/7 response time

Why Choose Us?

Committed to quality

One-year warranty on parts and labor

Guaranteed 24/7 response time

Frequently Asked Questions

Are all of your instrument repair & reconditioning services warrantied?

Do you offer any expedited options for repair & reconditioning services?

What is the typical turnaround for a controller or positioner reconditioning?

Depending on the type of damage, we’ve been able to repair and return controllers and positioners to our customers within 24 hours and no later than 72 hours. Contact our experienced engineering team to receive a custom quote and due date specific to your type of repair work.

How is the repair process different from the reconditioning process?

The Reconditioning and Repair Process at VIR follows the same procedures. The only difference is the source of the product. Reconditioned products are provided by VIR, whereas repaired products are provided by the customer.

All valves and instrumentation reconditioned and repaired by VIR are brought to CLASS-A Standards.

Our commitment to quality is delivered each and every time per our Standard Operating Procedures (SOPs).