Custom Valve Repair & Reconditioning Services

Class-A Process for Custom Valve Repair & Reconditioning Since 1984

At VIR, we provide complete reconditioning and repair of control valves, instrumentation,

accessories and parts within the U.S. and abroad

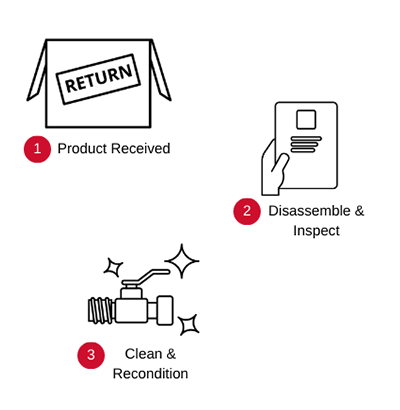

Our Class A ProcessMeets ANSI, ISA, ASME Standards

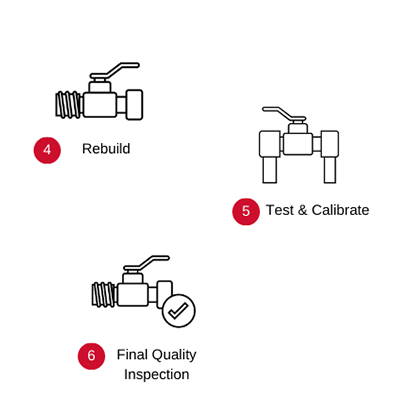

Following the reconditioning process, we rebuild the custom valve – then test and calibrate to ensure it is functioning reliably.

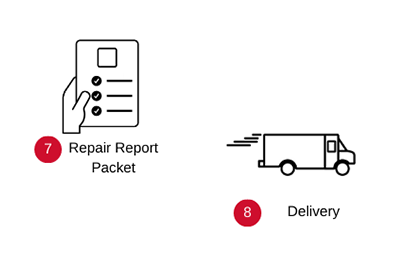

Finally, we ensure that the valves go through a final quality inspection and finalize our process with an “As Left” document, which is sent with the valve back to the customer.

Our Class A ProcessMeets ANSI, ISA, ASME Standards

Following the reconditioning process, we rebuild the custom valve – then test and calibrate to ensure it is functioning reliably.

Finally, we ensure that the valves go through a final quality inspection and finalize our process with an “As Left” document, which is sent with the valve back to the customer.

Why Choose Us?

Committed to quality

One-year warranty on parts and labor

Guaranteed 24/7 response time

Committed to quality

One-year warranty on parts and labor

Guaranteed 24/7 response time

Why Choose Us?

Committed to quality

One-year warranty on parts and labor

Guaranteed 24/7 response time

Frequently Asked Questions

What information do you need to determine if you can repair or recondition a custom valve?

We need an existing valve data sheet or digital pictures. If these options are not available, VIR offers field service that includes sending an employee to properly inspect the valve.

Are all your service options warrantied?

Yes – we warrant our work, products, and/or materials for (1) calendar year from the customer’s acceptance of the work, products, and/or materials.

Do you offer any expedited options for repair & reconditioning services?

Yes, VIR 24/7 service allows us to accommodate any customer’s emergency. Call us today at 713-991-3700 to speak with a VIR team member.

How is the reconditioning process different from the repair process?

The Reconditioning and Repair Process at VIR follows the same procedures. The only difference is the source of the product. Reconditioned products are provided by VIR, whereas repaired products are provided by the customer.

All valves and instrumentation reconditioned and repaired by VIR are brought to CLASS-A Standards.

Our commitment to quality is delivered each and every time per our Standard Operating Procedures (SOPs).